Analyzing the Impact of Fuel System Component Production Scalability on Manufacturers

allpaanel mahadev book, lotus book 365 registration, laserbook 247:Analyzing the Impact of Fuel System Component Production Scalability on Manufacturers

In the world of manufacturing, scalability is a crucial factor that can make or break a company’s success. The ability to scale up or down production of fuel system components can have a significant impact on a manufacturer’s bottom line. In this article, we will explore the importance of scalability in fuel system component production and how it can affect manufacturers.

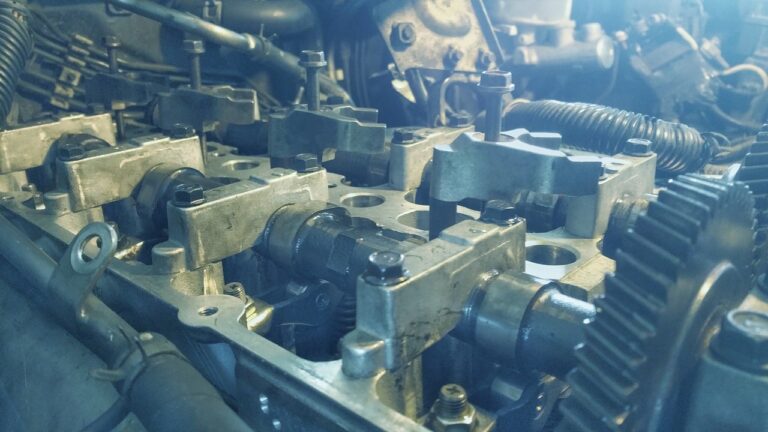

Fuel system components, such as fuel pumps, injectors, and filters, play a critical role in the performance and efficiency of vehicles. Manufacturers of these components must be able to produce them in large quantities to meet the demand of the automotive industry. However, the ability to scale up production quickly and efficiently can be a challenge for many manufacturers.

One of the key benefits of scalability in fuel system component production is the ability to respond to changes in demand. For example, if there is a sudden increase in demand for a particular type of fuel injector, a manufacturer with scalable production capabilities can quickly ramp up production to meet this demand. On the other hand, a manufacturer without the ability to scale up production may struggle to meet this increased demand, leading to lost sales opportunities.

Scalability also allows manufacturers to take advantage of economies of scale. By producing fuel system components in large volumes, manufacturers can reduce their per-unit production costs, leading to higher profit margins. This cost savings can be passed on to customers in the form of lower prices, making the manufacturer more competitive in the market.

Furthermore, scalability can help manufacturers to improve their operational efficiency. By streamlining production processes and automating repetitive tasks, manufacturers can increase their production output without significantly increasing their labor costs. This can lead to higher productivity and faster turnaround times, which can improve customer satisfaction and loyalty.

However, scalability in fuel system component production is not without its challenges. Manufacturers must invest in advanced manufacturing technologies and equipment to achieve scalability, which can be costly. Additionally, scaling up production too quickly can lead to quality control issues and production delays, which can harm a manufacturer’s reputation and bottom line.

In conclusion, the ability to scale up or down production of fuel system components can have a significant impact on manufacturers. Scalability allows manufacturers to respond to changes in demand, take advantage of economies of scale, and improve operational efficiency. However, achieving scalability requires investment in advanced technologies and equipment, as well as careful planning to avoid quality control issues. By understanding the importance of scalability and implementing strategies to achieve it, manufacturers can position themselves for long-term success in the competitive automotive industry.

FAQs

Q: What are some common challenges manufacturers face when scaling up production of fuel system components?

A: Some common challenges include the need for investment in advanced technologies and equipment, potential quality control issues, and production delays.

Q: How can manufacturers benefit from achieving scalability in fuel system component production?

A: Manufacturers can benefit from scalability by being able to respond to changes in demand, take advantage of economies of scale, and improve operational efficiency.

Q: What are some strategies manufacturers can use to achieve scalability in fuel system component production?

A: Some strategies include investing in advanced manufacturing technologies and equipment, streamlining production processes, and automating repetitive tasks.