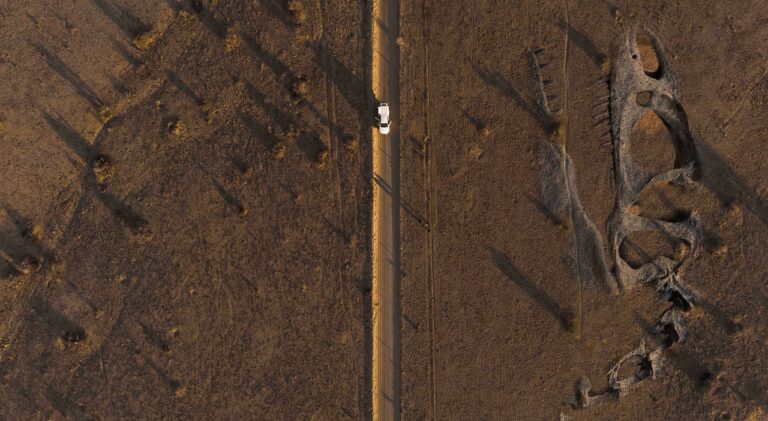

Automotive Industry and Smart Manufacturing

The adoption of smart manufacturing practices in the automotive industry comes with its fair share of challenges. One key obstacle is the high initial investment required to implement advanced technologies such as automation, machine learning, and artificial intelligence. Many automotive manufacturers may find it difficult to justify the upfront costs associated with upgrading their production processes, especially when the return on investment is not immediately tangible.

Another significant challenge is the lack of skilled workforce needed to operate and maintain the new technologies effectively. As smart manufacturing systems become increasingly complex and interconnected, there is a growing demand for workers with specialized technical skills and expertise. However, finding and retaining qualified personnel in this rapidly evolving field can be a daunting task for automotive companies, leading to potential delays and inefficiencies in the implementation of smart manufacturing practices.

Emerging Technologies Revolutionizing Automotive Manufacturing Processes

Over the past few years, the automotive industry has witnessed a significant shift towards adopting emerging technologies in their manufacturing processes. One such technology is additive manufacturing, commonly known as 3D printing, which is revolutionizing the way components and prototypes are developed in the automotive sector. This technology allows for quick and cost-effective production of complex parts, leading to faster innovation and reduced lead times in the production cycle.

Another groundbreaking technology making waves in automotive manufacturing is the Internet of Things (IoT). IoT enables manufacturers to connect and monitor various devices and machines in real-time, providing valuable data insights to optimize production efficiency and quality control. By harnessing the power of IoT, automotive companies can improve predictive maintenance, streamline operations, and enhance overall productivity on the factory floor.

Additive manufacturing, or 3D printing, allows for quick and cost-effective production of complex parts

Reduces lead times in the production cycle

Internet of Things (IoT) enables real-time monitoring and data insights

Optimizes production efficiency and quality control

Improves predictive maintenance and streamlines operations

Enhances overall productivity on the factory floor

Benefits of Adopting Smart Manufacturing Practices in Automotive Production

Shifting towards smart manufacturing practices in the automotive industry has shown significant benefits in enhancing production efficiency and product quality. By integrating advanced technologies like artificial intelligence, machine learning, and IoT devices, manufacturers can optimize their operations, reduce operational costs, and minimize errors in the production process. This results in improved productivity and streamlined workflows, ultimately leading to higher output and customer satisfaction. Moreover, the real-time data analytics provided by smart manufacturing tools enable manufacturers to make informed decisions promptly, enhancing overall operational agility and responsiveness to market demands.

Another key benefit of adopting smart manufacturing practices in automotive production is the increased customization capabilities it offers. With the ability to collect and analyze vast amounts of data, manufacturers can better understand customer preferences and market trends, allowing for the creation of more personalized products. This customization not only enhances customer satisfaction but also opens up new revenue streams by catering to niche markets and offering unique products tailored to specific consumer needs. In a competitive industry like automotive manufacturing, the ability to quickly adapt and deliver customized products gives companies a significant advantage in attracting and retaining customers.

What are some key challenges in implementing smart manufacturing in the automotive industry?

Some key challenges include the high initial investment costs, the need for skilled workforce to operate and maintain new technologies, and potential resistance to change from employees.

How are emerging technologies revolutionizing automotive manufacturing processes?

Emerging technologies such as artificial intelligence, Internet of Things, and robotics are revolutionizing automotive manufacturing processes by improving efficiency, reducing errors, and enabling real-time data analysis.

What are some benefits of adopting smart manufacturing practices in automotive production?

Some benefits include increased productivity, reduced downtime, improved quality control, better supply chain management, and overall cost savings.