Future Directions in Fuel System Component Augmented Reality Maintenance Guides

all panel login mahadev book, lotus bhai.com, laser book 247 com registration:Future Directions in Fuel System Component Augmented Reality Maintenance Guides

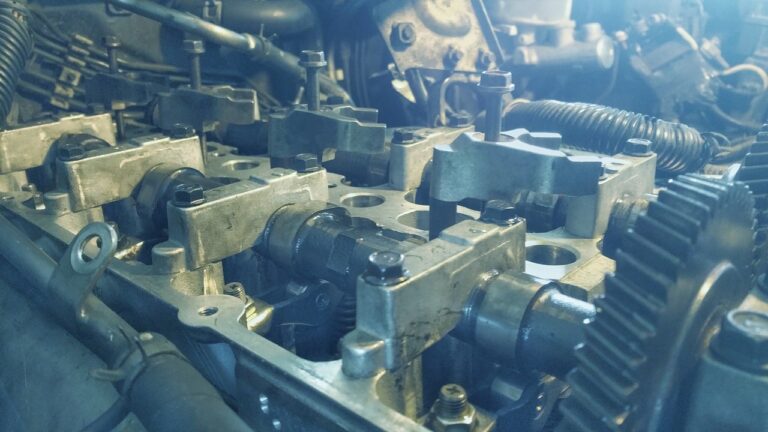

In today’s fast-paced world, technology continues to revolutionize various industries, including the automotive sector. One of the recent advancements in this field is the use of augmented reality (AR) in maintenance guides for fuel system components. This technology offers a futuristic approach to troubleshooting and repairing issues with fuel system components, enhancing efficiency and accuracy in maintenance tasks.

Augmented reality overlays digital information onto the real environment, providing users with detailed instructions and visual representations of complex systems. When applied to fuel system maintenance, AR guides can offer step-by-step instructions, 3D models, animations, and interactive interfaces to assist technicians in identifying and addressing issues effectively.

Here, we will explore the future directions of fuel system component AR maintenance guides and how they can benefit the automotive industry.

Enhanced Visualization Capabilities

One of the key advantages of AR maintenance guides for fuel system components is their enhanced visualization capabilities. By utilizing AR technology, technicians can access detailed 3D models of fuel system components, allowing them to visualize the inner workings of complex systems with precision. This visual aid can help technicians identify potential issues, locate specific parts, and understand the assembly process more effectively.

Furthermore, AR maintenance guides can provide interactive overlays on physical components, highlighting key areas of interest and providing real-time data on component performance. This visual guidance can streamline the maintenance process, reduce errors, and enhance overall efficiency in fuel system maintenance tasks.

Improved Training and Skill Development

Another significant benefit of fuel system component AR maintenance guides is their potential to enhance training and skill development for technicians. By incorporating AR technology into maintenance guides, automotive companies can create immersive training experiences that simulate real-world scenarios and facilitate hands-on learning.

AR maintenance guides can offer interactive training modules, virtual simulations, and gamified exercises that allow technicians to practice troubleshooting and repair tasks in a safe and controlled environment. This approach can help technicians develop their skills, improve their proficiency in maintenance tasks, and ultimately enhance the quality of service provided to customers.

Remote Assistance and Collaboration

Fuel system component AR maintenance guides also have the potential to revolutionize remote assistance and collaboration in the automotive industry. By leveraging AR technology, technicians can receive real-time support and guidance from experts located in different locations, facilitating remote troubleshooting and problem-solving.

AR maintenance guides can enable technicians to share live video feeds, annotations, and voice communication with remote experts, allowing them to collaborate effectively on complex maintenance tasks. This remote assistance functionality can reduce the need for in-person support, minimize downtime, and improve the speed and accuracy of maintenance operations.

Integration with IoT and Data Analytics

As fuel system components become increasingly connected through the Internet of Things (IoT) technology, AR maintenance guides can also be integrated with data analytics and predictive maintenance systems to enhance performance monitoring and diagnostics. By combining AR technology with IoT sensors and data analytics, technicians can access real-time information on component status, performance metrics, and potential issues.

AR maintenance guides can overlay diagnostic data, predictive maintenance alerts, and recommended actions onto physical components, providing technicians with valuable insights into the health of fuel system components. This integration can help automotive companies optimize maintenance schedules, prevent costly repairs, and prolong the lifespan of fuel system components.

Personalized User Interfaces and Customization

In the future, fuel system component AR maintenance guides are likely to offer personalized user interfaces and customization options that cater to the specific needs and preferences of technicians. By allowing users to customize their AR guides, automotive companies can enhance user experience, promote engagement, and improve the effectiveness of maintenance tasks.

AR maintenance guides may offer adjustable settings, language options, interactive tutorials, and tailored content based on user feedback and performance data. This customization can empower technicians to tailor their maintenance guides to their individual learning styles, skill levels, and work environments, fostering a more personalized and effective maintenance experience.

Integration with Augmented Reality Glasses and Wearables

As augmented reality technology continues to evolve, fuel system component AR maintenance guides are expected to leverage advancements in AR glasses and wearables to enhance user experience and accessibility. By integrating AR maintenance guides with AR glasses and wearables, technicians can access hands-free instructions, visual cues, and interactive interfaces while working on fuel system components.

AR glasses and wearables can provide technicians with heads-up displays, voice commands, and gesture controls that streamline the maintenance process and improve workspace safety. This integration can empower technicians to access critical information and guidance without the need to refer to external devices, enhancing their productivity and efficiency in maintenance tasks.

Overall, the future directions of fuel system component AR maintenance guides offer exciting possibilities for the automotive industry. By embracing AR technology, automotive companies can enhance visualization capabilities, improve training and skill development, facilitate remote assistance and collaboration, integrate with IoT and data analytics, offer personalized user interfaces, and leverage AR glasses and wearables to revolutionize maintenance tasks for fuel system components.

FAQs

Q: How do AR maintenance guides enhance visualization capabilities for fuel system components?

A: AR maintenance guides provide detailed 3D models, animations, and interactive overlays that help technicians visualize the inner workings of complex fuel system components with precision.

Q: Can AR maintenance guides improve training and skill development for technicians?

A: Yes, AR maintenance guides offer immersive training experiences, interactive simulations, and gamified exercises that facilitate hands-on learning and skill development for technicians.

Q: How do AR maintenance guides enable remote assistance and collaboration in the automotive industry?

A: AR maintenance guides allow technicians to receive real-time support, share live video feeds, and collaborate with remote experts to troubleshoot and solve issues effectively.

Q: What are the benefits of integrating AR maintenance guides with IoT and data analytics?

A: By combining AR technology with IoT sensors and data analytics, technicians can access real-time information on component status, performance metrics, and potential issues to optimize maintenance schedules and prevent costly repairs.

Q: How can AR maintenance guides be personalized and customized for technicians?

A: AR maintenance guides offer adjustable settings, language options, interactive tutorials, and tailored content based on user feedback and performance data to cater to the specific needs and preferences of technicians.

Q: How do AR maintenance guides leverage AR glasses and wearables to enhance user experience?

A: By integrating with AR glasses and wearables, AR maintenance guides provide hands-free instructions, visual cues, and interactive interfaces that streamline the maintenance process and improve workspace safety for technicians.