Future Prospects of Fuel System Component Material Recycling Technologies

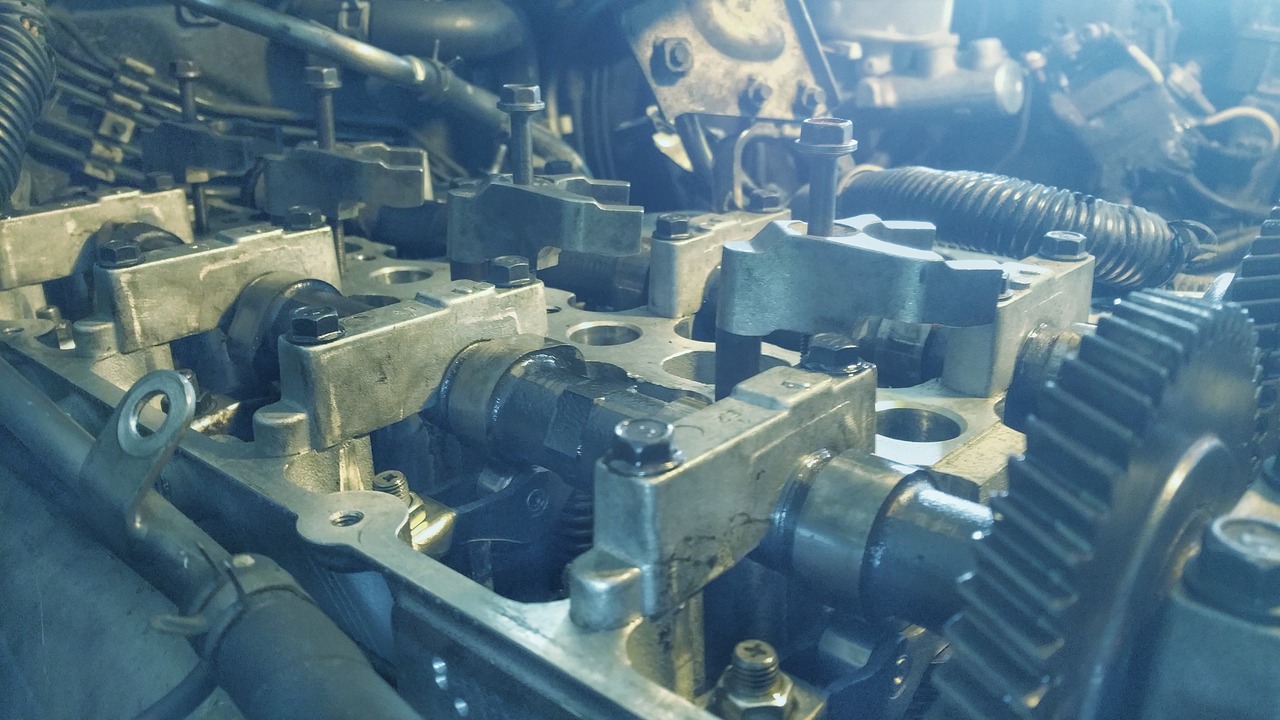

all pannel.com, laser247.com, betbook247:Fuel systems are vital components of any vehicle, playing a crucial role in delivering fuel to the engine for combustion. However, as the automotive industry shifts towards more sustainable practices, the need for recycling technologies for fuel system component materials is becoming increasingly important. In this article, we will explore the future prospects of these technologies and their impact on the industry.

Recycling technologies have come a long way in recent years, with advancements in materials science and engineering making it possible to recover valuable materials from end-of-life fuel system components. These technologies not only help reduce the environmental impact of discarded materials but also provide an economic incentive for manufacturers to adopt more sustainable practices.

One of the key drivers of recycling technologies for fuel system component materials is the growing demand for materials such as plastics, metals, and rubber. With the increasing global population and the rise of emerging economies, the demand for these materials is expected to continue growing in the coming years. By recycling these materials from end-of-life fuel system components, manufacturers can reduce their reliance on virgin materials and create a more circular economy.

In addition to the environmental and economic benefits, recycling technologies for fuel system component materials also present opportunities for innovation and product development. By recovering materials from discarded components, manufacturers can explore new ways to design and manufacture fuel system components, leading to more efficient and sustainable products.

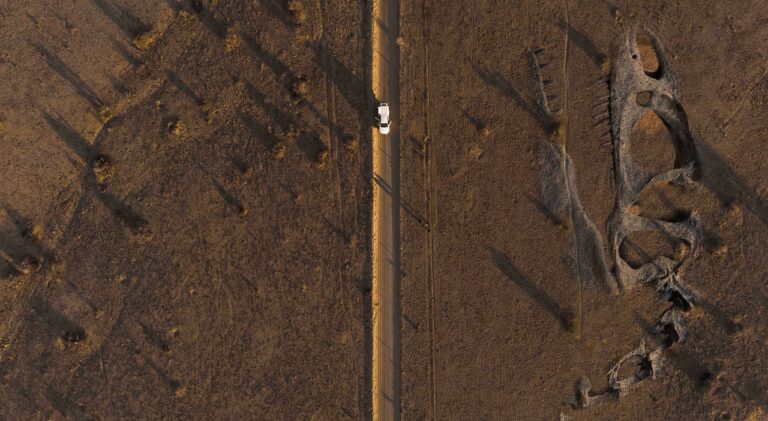

Furthermore, recycling technologies can help reduce the amount of waste generated by the automotive industry, ultimately leading to a cleaner and healthier environment. As consumers become more environmentally conscious, the demand for sustainable products and practices is expected to increase, driving the adoption of recycling technologies for fuel system component materials.

Overall, the future prospects of recycling technologies for fuel system component materials are promising, with potential benefits for both the industry and the environment. By investing in these technologies, manufacturers can create a more sustainable supply chain and reduce their environmental footprint.

Heading 1: The Importance of Recycling Technologies for Fuel System Component Materials

Heading 2: Advances in Materials Science and Engineering

Heading 3: Economic Incentives for Manufacturers

Heading 4: Growing Demand for Materials

Heading 5: Opportunities for Innovation and Product Development

Heading 6: Environmental Benefits of Recycling Technologies

Heading 7: Consumer Demand for Sustainable Products

Heading 8: Conclusion

In conclusion, the future of recycling technologies for fuel system component materials looks promising, with potential benefits for manufacturers, consumers, and the environment. By investing in these technologies, the automotive industry can move towards a more sustainable and circular economy, reducing waste and creating new opportunities for innovation. As the demand for sustainable products continues to grow, recycling technologies will play a crucial role in shaping the future of the industry.

—

FAQs

Q: How do recycling technologies for fuel system component materials work?

A: Recycling technologies involve collecting end-of-life fuel system components, separating and sorting materials, and processing them to recover valuable materials such as plastics, metals, and rubber.

Q: What are the benefits of recycling technologies for the automotive industry?

A: Recycling technologies help reduce the industry’s environmental impact, create economic incentives for manufacturers, drive innovation and product development, and meet consumer demand for sustainable products.

Q: Are recycling technologies cost-effective for manufacturers?

A: While there may be initial costs associated with implementing recycling technologies, the long-term benefits in terms of reduced material costs and improved brand reputation make them a cost-effective investment for manufacturers.